SUSTAINABILITY

SUSTAINABILITY AS A FUTURE INVESTMENT

Leather is a natural product. It combined unique material characteristics such as durability, dimensional stability and breathability with an exclusive, beautiful appearance Outstanding product quality is a given for us. Excellent product quality is a matter of course for us. What’s more, we are committed to supporting the environment by continuously reducing our carbon footprint, water consumption and emissions.

TRENDSETTING AND COMPREHENSIVE

For decades, we’ve been focussing on effective solutions for the disposal areas from raw goods to crust leather. At the heart of our efforts was the goal to obtain bioenergy (electricity and heat) from by-products as a result of leather production. Thanks to widespread investments, we have been able to develop an environmental protection programme unique to the industry, which combines the economical and environmental aspects of our actions in a harmonious way.

PROCESS WATER TREATMENT

Since 1986, we have operated our own process water treatment plant. This enables us to feed chemically/physically pre-treated water for complete organic treatment into the Hof/Saale sewage treatment plant. Pre-cleaning removes over 99% of pollutants and 90% of dirt content from the water. This form of pre-treatment is characterised by its high flexibility, even in the event of heavy fluctuations in waste water quantity/properties. Following funding approval from the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU), plant construction began in 2012. The official start-up took place on 12 June 2013.

It’s best treated ourselves!

haben wir uns in Bezug auf unser Abwasser gesagt.

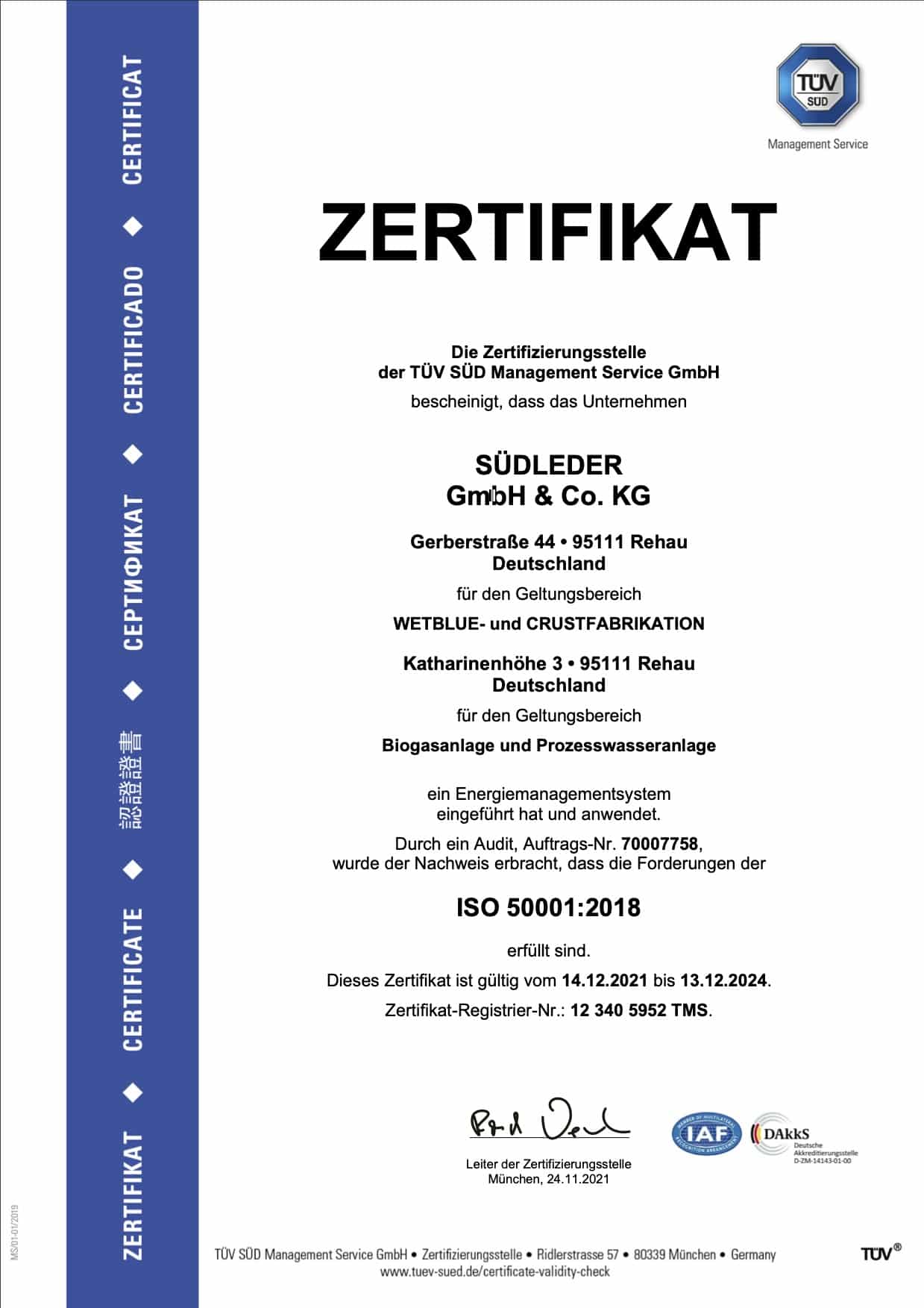

BIOENERGY PLANT

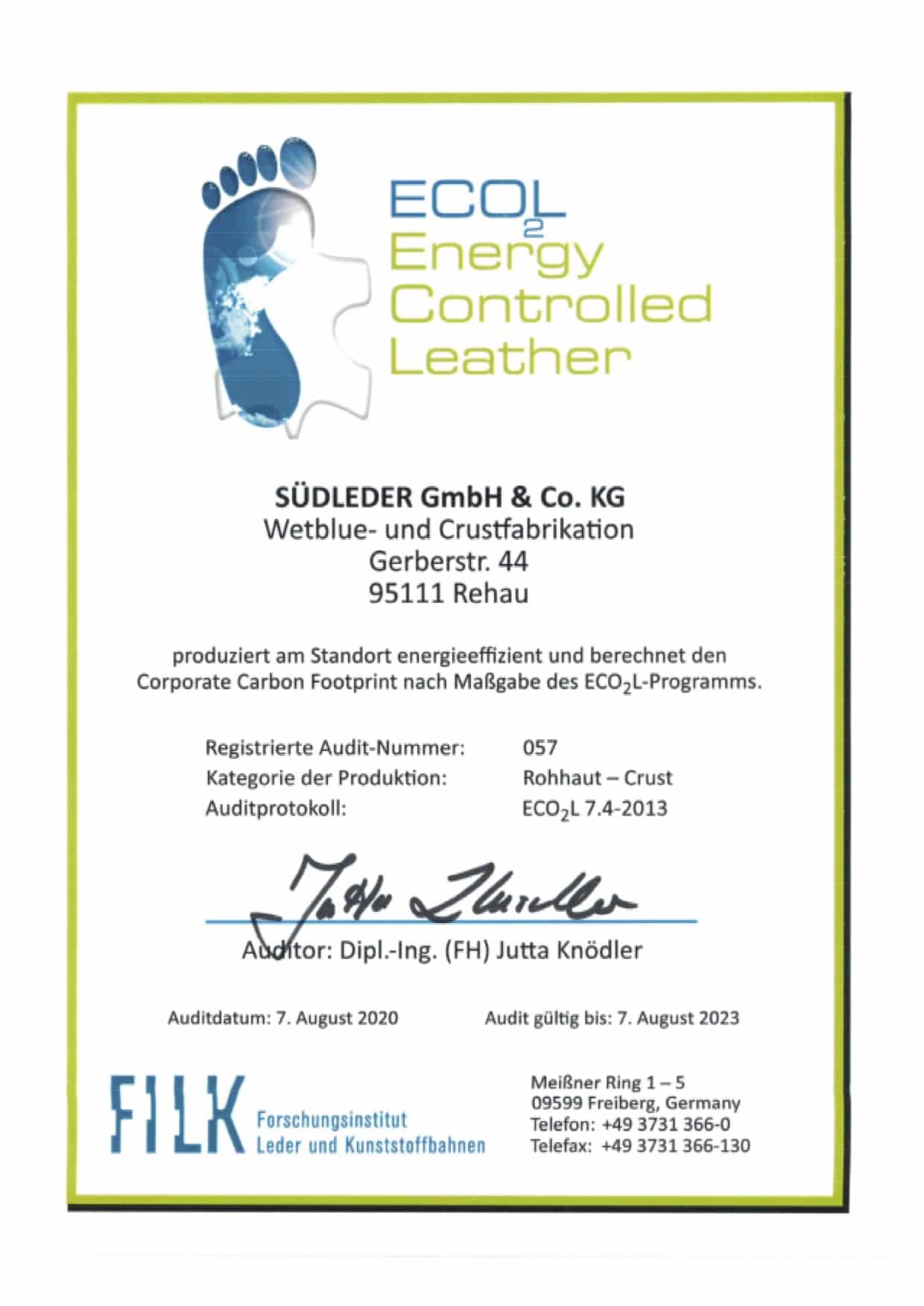

We focus on sustainable leather processing that is continuously further developed and optimised to protect the environment and future generations. An innovative approach helps us to overcome the challenges of today, tomorrow and years to come. This includes:

the sparing and careful use of resources

environmentally friendly production processes

sensible use of all by-products

company-internal process water treatment

energy production from waste material

significant reduction in CO2

QUALITY AND SUSTAINABILITY IS OUR TOP PRIORITY

Flexible production volumes, fast response times and high quality requirements are daily challenges that we overcome to satisfy our customers’ needs. At the same time, we’re always sure to handle resources responsibly along with a sustainable, environmentally aware approach. Thanks to decades of experience, state-of-the-art production technology and comprehensively certified quality management, we are able to meet these requirements with ease and even exceed them.

All work steps are stringently monitored and continuously inspected. We only use top-quality, tested chemicals and tools from certified suppliers. Our data system ensures that detailed information about the hide and leather is available for our customers. Participation in ring trials with accredited laboratories ensures the accuracy of our laboratory analyses.

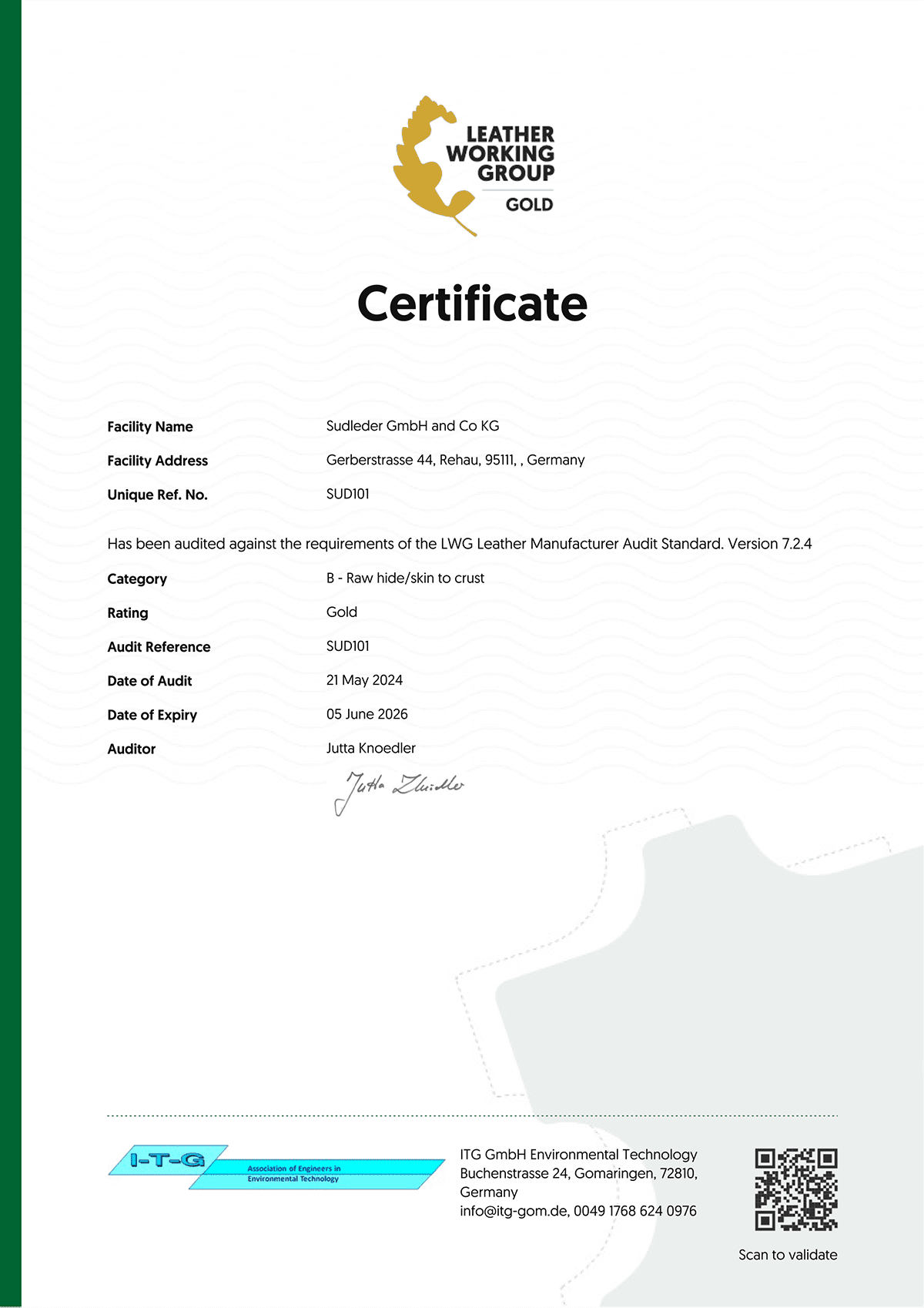

CERTIFIED QUALITY

The market is always demanding more from tanneries: flexible production volumes, fast response times and outstanding quality. These requirements can only be met by understanding the balance between quality and quantity. We’re particularly good at this thanks to decades of experience, innovative production techniques and comprehensive quality management. We’re just as strong when it comes to quality matters.

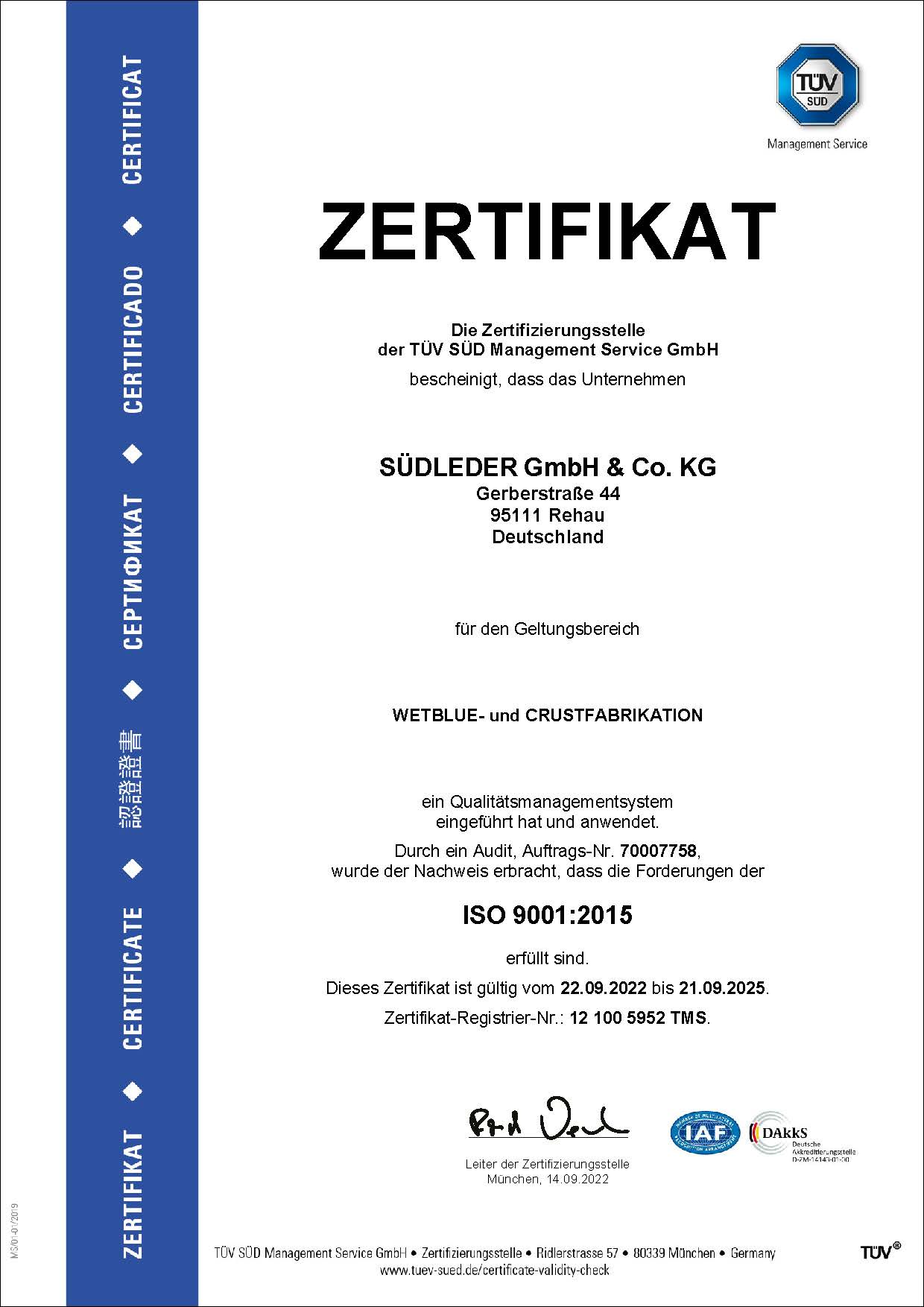

This is guaranteed in part by our experience with leather as a material, as well as our quality management certified in line with DIN EN ISO 9001:2015. It contains all of the work steps: from careful inspection of the customer goods supplied, analytical incoming goods inspection of tools used and the work of our skilled team that enables all customer requirements to be perfectly implemented through to quality production and delivery of the ordered goods. Our data system ensures that detailed information about the hide and leather is available for our customers.

Participation in ring trials with accredited laboratories ensures the accuracy of our laboratory analyses. We only use top-quality, tested chemicals and tools from certified suppliers.

PARTNERS

SÜDLEDER ist Mitglied Verband der Deutschen Lederindustrie e.V.

Weitere Informationen finden Sie unter: www.vdl-web.de

SÜDLEDER ist Mitglied im Arbeitgeberverband der Deutschen Lederindustrie e.V.

Weitere Informationen finden Sie unter: www.vbu-net.de

SÜDLEDER ist Mitglied bei „Leather Naturally“

Leather Naturally ist ein gemeinnütziger Industrie-Mitgliedsverband, der sich auf die Information zu und Förderung von Leder konzentriert. Leather Naturally fördert die Verwendung von weltweits, nachhaltig hergestelltem Leder und versucht, Designer, Schöpfer und Verbraucher zu inspirieren und über dessen Schönheit, Qualität und Vielseitigkeit zu informiere Weitere Informationen finden Sie unter www.leathernaturally.org